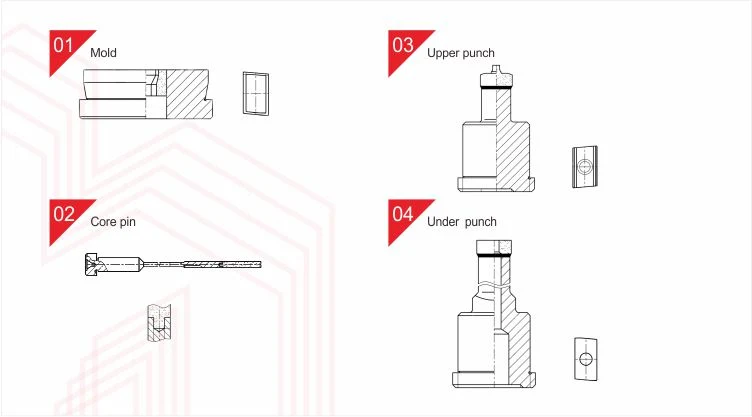

Carbide Thermos Flask Liner Drawing Dies for Pressing Thermos Flask Liner

Powder forming mold is to put powder into the to compress, solidify, and sinter at high temperature to form

high-precision parts, which can be mass producted. The use of high-precision molds omits the cutting waste after

forming and sintering, and achieves the purpose of reducing costs.

We customize carbide molds for customers, we accept customized drawings. According to the customer's drawings,

we understand the customer's specific needs, and carry out professional customization. So every product is carefully

designed and manufactured, our efforts are only for customer's satisfaction.

Mould Type | Tungsten Carbide Powder Metallurgy Mould |

Design Software | UG, ProE, Auto CAD, Solidworks, etc. |

Precision(mm) | 0.002 |

Hardness HRA | HRA58-62 |

Service Life | 100000 to 300000 times |

Equipments | High speed CNC, standard CNC, EDM, Wire cutting, Grinder, Lathe, Milling machine, plastic injection machine |

Surface Finish | Plating, Polishing, Heat treatment |

Material | Stainless Steel, Brass, Copper, Aluminum, Steel, Carbon Steel etc. |

Service | OEM &ODM service |

Size | Customized |

1. Near-net shape products can be manufactured through molds.

2. Suitable for materials that are difficult to process.

3. Quick installation system can not only reduce the time to install the mold, but also reduce the damage rate of the

mold.

4. Usually, multiple air holes are embedded in the product, and the visible density is lower than the true density,

which reduces the weight of the product.

5. Use lubricating oil by using air holes. No oil supply is required.

1.Direct factory sale.

1.Direct factory sale.2.Reasonable price.

3.good wear resistance.

4.Longer service life.

5.OEM service available.

6.Short and on time delivery.

7.Samples and small orders are acceptable.

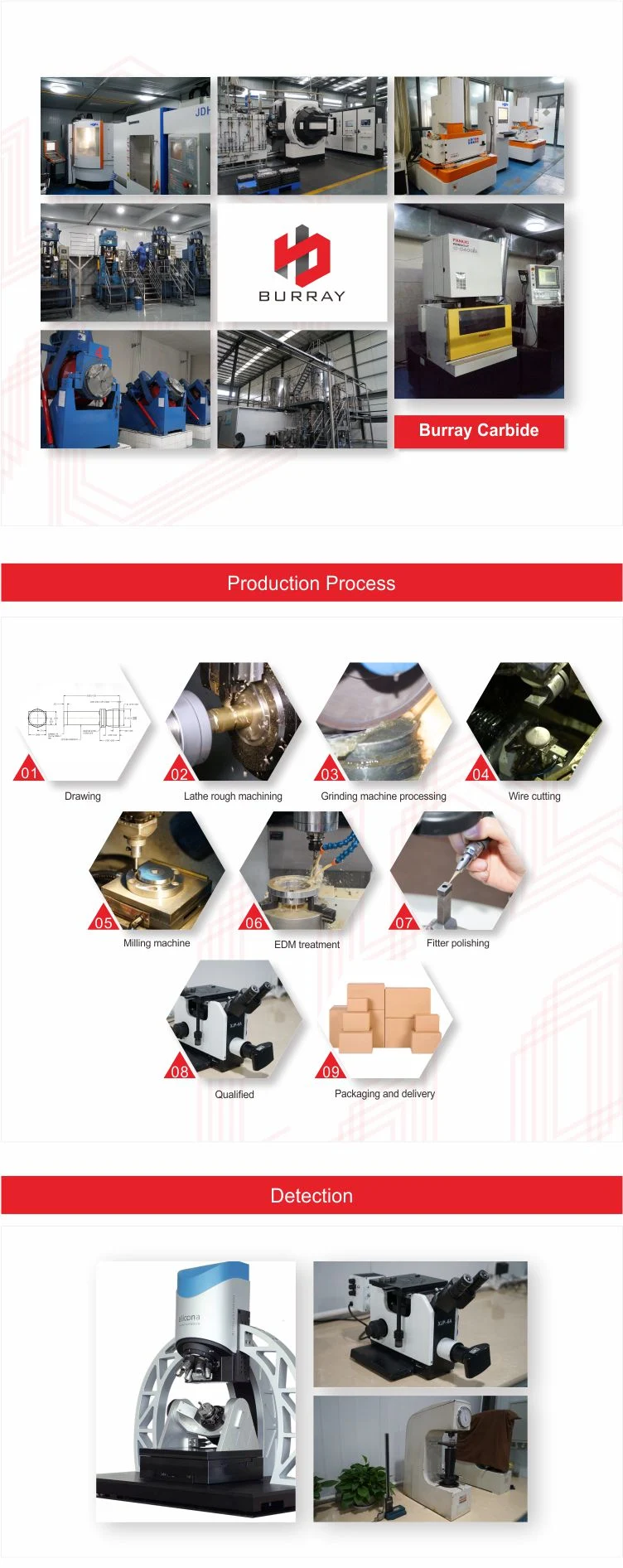

Every part is carefully processed (by grinding, machining, milling, wire-cutting, EDM etc) to the exact tolerances shown

on the drawing and carefully checked both in production line and QC room (QC check every dimension of every part

before packing and shipping). In this way, we assured the high precision and thus the interchangeability in the tool

room of the customers' factory.

1.Plastic case filling sponges, and foam. cotained in wooden/carton case.

2.Special packaging according to clients' requirments.

3.Shipping: Shenzhen, Chongqing, Shanghai, Qingdao, Guangzhou,etc. We accept land, air, sea transport and

international multimodal transport.

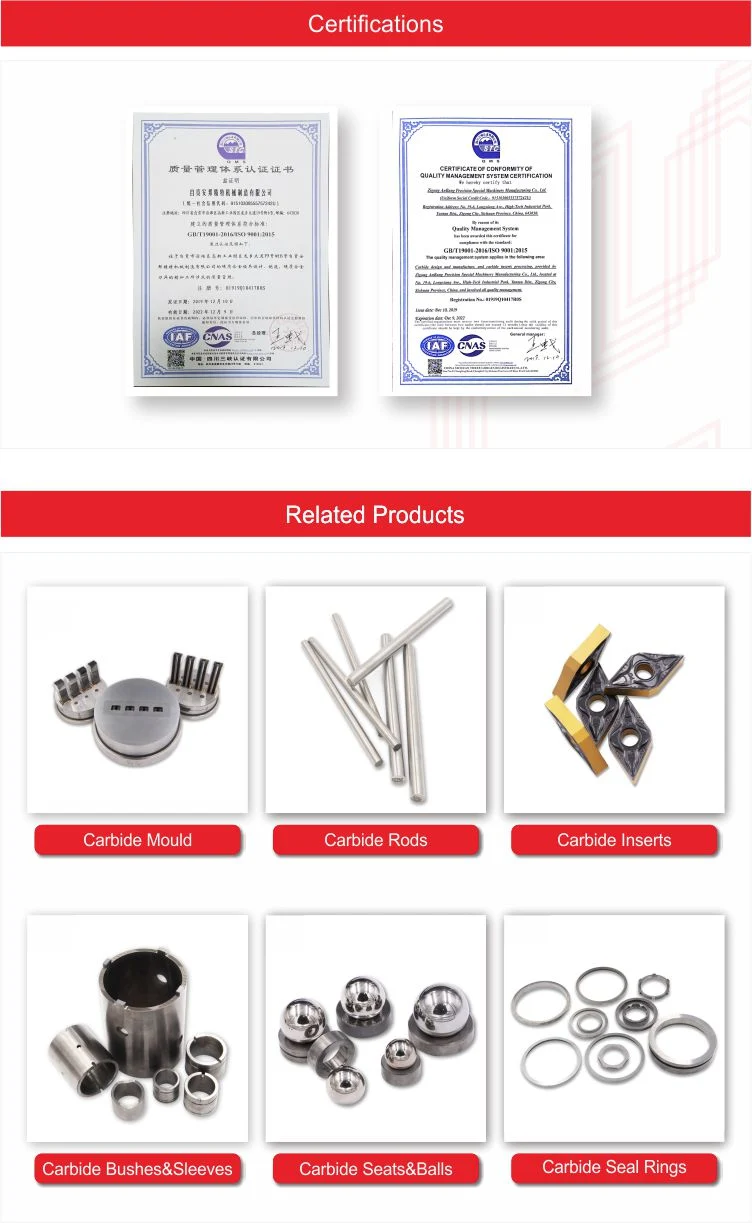

Sichuan Burray Cemented Carbide Co.,Ltd. is a professional high-tech enterprise, specialized in high-performance

carbide R&D, design, manufacture, marketing sales, products including cemented carbide precision dies, cutting

tools, wear-resisting parts, carbide profiles, etc. It covers an area of over more than 20 mu with7,800 sq.ft standard

workshop and 5'500 sq.ft R&D office. Burray has many high-quality technical and management personnel who have

strong technical strength and rich processing production experience. We are able to make different kinds of special

customized cemented carbide products with ±0.002mm machining precision. Our products are widely applied to the

following fields: machine manufacturing, metallurgy, mining, oil, electronics, space industry, etc.

Q1: Are you a trading company or manufacturer?

A1: We are a manufacturer of tungsten carbide mould. Our factory located in Zigong City, Sichuan Province. Welcome

to visit our factory!

to visit our factory!

Q2: What about the package?

A2: We use plastic boxes to pack our products, and filled plastic is shockproof and transported in cartons. also It can

make as you need and depend on the shapes of the product.

make as you need and depend on the shapes of the product.

Q3: What is your minimum order requirement?

A3: OEM and customization are available. we accept the small trial order, big order will get a big discount. and try our

best to service our customers.

best to service our customers.

If you have another question, pls feel free to contact us as below: