- The line is designed and constructed by KPACK. Client contacts with one window only from the contract signature, normal production and after service;

- Each of equipment designed according to Food & Drug sanitary standard, which guarantees the hygiene of the products;

- Most optimized and efficient design according to customer's requirements;

- Whole line is designed with automatic control system.

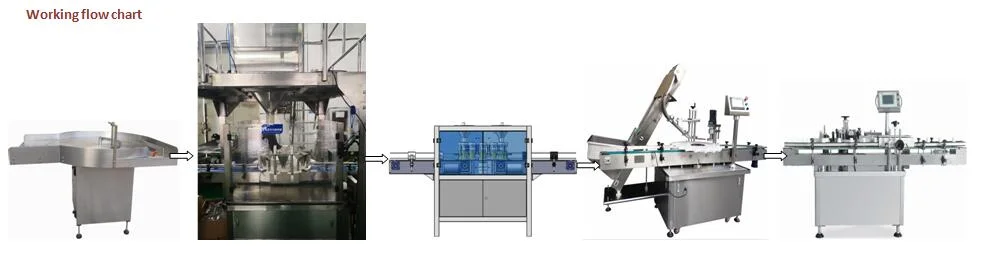

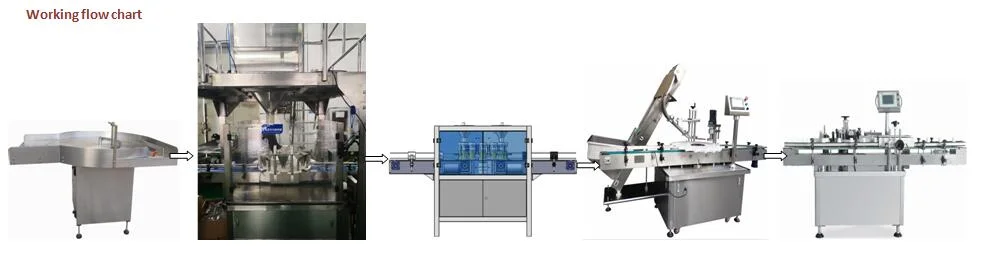

- The line which covers the equipment as below

Unscrambler------Multi-heads weigher------workingplatform-----Cans filling machine-----check weigher-----Caps feeder&sealer------Labelling machine

1. Equipped with safety protection, comply with firm's safety management requirements.

2. Flexible applications for Grain, Granule, or Granules mixing liquids materials Bottling or Canning by change differenct dosing equipments. Granule and Grain products dosing by Multi-heads weigher or Liner Weigher. Liquids products dosing by Piston filler or Pump.

3. Use PLC Servo System and pneumatic control system and super touch screen to compose the drive control center which maximize the whole machine's control precision,reliability and intelligentized level.

4. Touch screen can store the technical parameters of various kinds of products ,it is unnecessary to reset while products changing.

5. With error indicating system , which help to handle the trouble immediately.

6. Available to connect with the Capping machine, check weigher, Labelling machine and cartoning machine to get the whole bottles or Cans packaging line.

1. Equipped with safety protection, comply with firm's safety management requirements.

2. Flexible applications for Grain, Granule, or Granules mixing liquids materials Bottling or Canning by change differenct dosing equipments. Granule and Grain products dosing by Multi-heads weigher or Liner Weigher. Liquids products dosing by Piston filler or Pump.

3. Use PLC Servo System and pneumatic control system and super touch screen to compose the drive control center which maximize the whole machine's control precision,reliability and intelligentized level.

4. Touch screen can store the technical parameters of various kinds of products ,it is unnecessary to reset while products changing.

5. With error indicating system , which help to handle the trouble immediately.

6. Available to connect with the Capping machine, check weigher, Labelling machine and cartoning machine to get the whole bottles or Cans packaging line.

| Model | KP-50 | |

| Measure method | Electroni weigher/Piston filler/Pump | |

| Sealing height | 50-200mm | |

| Filling weight | Max5000ml | |

| Packaging precision | ≤0.3-1% | |

| Packaging speed | Max50pcs/min (Depend on the product characteristic) | |

| Power supply | Three phase 380/220V 50-60Hz / 2kw | |

| Pressure | 6-8 kg/cm2 0.3m3/min | |

| weight | 500kg | |

| Dimension (mm) | 3000x900x1800mm | |